If you are planning a hot forging aluminum process, there are a number of things that you need to get correct. There are things that will make the process a success and produce the desired quality of the forged aluminum product.

Note that the hot forging aluminum process can produce a range of products, as you can see here in hot forging china stores. But you need to get these 5 things correct.

Preparing Material

The first thing that you must get right is the material. What kind of aluminum do you need for the kind of products that you need? This is a very important factor because it will affect all the other stages. There is a range of aluminum metals you select from, including the many alloys. The properties you are looking for in the forged part are the most important thing. It will help you get the right aluminum.

-

Forging temperature

The second you need to get correct for a perfect hot forging aluminum is the forging temperature. The forging temperature is simply the temperature you need to reach for the workpiece to reach crystallization. That is when it will be ready for hot forging. With so many varieties of aluminum materials, you need to check the hardness and determine the correct crystallization temperature.

-

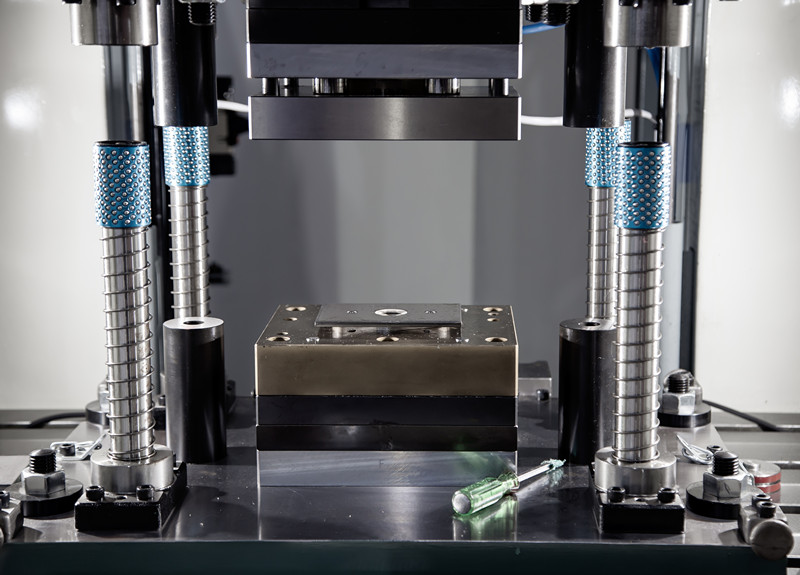

Making Dies

The other thing that you need to consider in the hot forging aluminum process is the dies. The making of the dies is a bit tricky because it takes into consideration a number of things. The first thing is the material of the mold and, in this case, the type of steel. It must have a higher forging temperature than the workpiece. The other thing you need to consider the size and shape of the product you need to forge when making dies.

-

Treatment

After hot forging aluminum, the next stage is treatment. The treatment process is usually determined by the properties needed in the forged products. You need to use the temperature variations to ensure the correct hardness of the materials has been realized. Make sure that you have followed the entire process.

-

Finishing

The other thing that you must get right in the hot forging aluminum process is the finishing work. You must ensure the forged part has achieved the desired shape and size. This is crucial because it will determine the quality. The finishing stage should make use of quality machining equipment to produce fine products.